Double-ply Bellows

- Less stress (50% reduced), force, and torsion exerted on the double-layered bellows than conventional single-layered bellows results in increased lifespan of bellows

- Corrosion resistance materials such as stainless steel 316L and double layered structure are adopted to minimize corrosion.

- Double-ply bellows is good for the locations on which higher internal pressure is applied because of the double layered and corrugated structure.

- Process Applications – Ti/TiN depo, USG depo, TEOS, W-plug, BPSG, PE-SiON, PE-SiO2, inside gas scrubber

LFD (Lamina Flow Double-ply) Bellows

- LFD (Lamina Flow Double-ply) bellows

- In addition to the functions of Double-ply bellows, corrosion resistant stainless steel liner is added to improve gas flow inside bellows from troublesome turbulent gas flow into lamina flow.

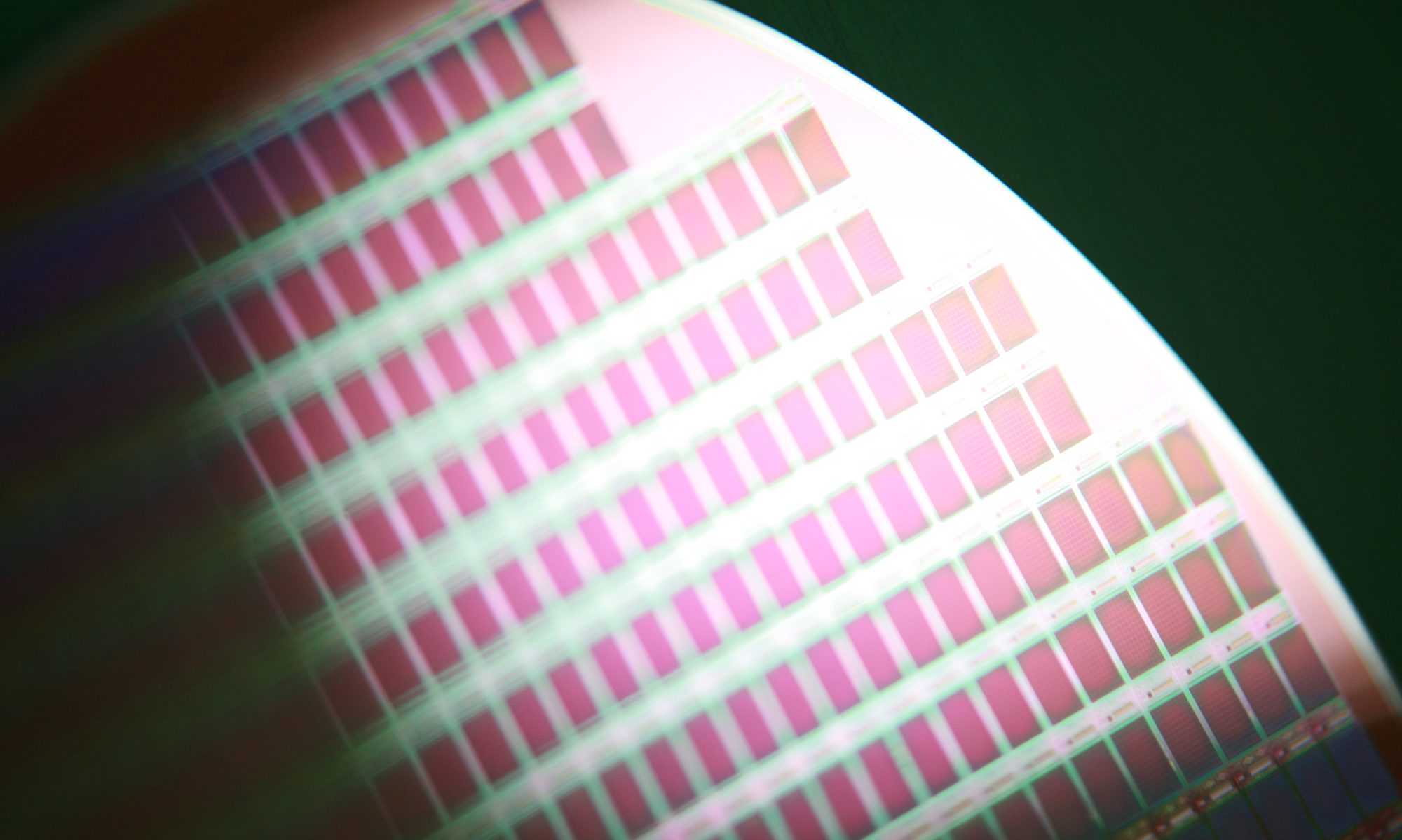

- Accordingly, preventing outer ply of bellows from pitting corrosion, thermal corrosion, and stress corrosion lead to longer life span of bellows and contamination-free semiconductor manufacturing environment.

If you need more information, please leave your contact information. Contact Us